We have built sophisticated facility of infrastructure, equipped with ultramodern amenities and its operations are appropriately carried out by highly specialized team of experts. Here, we have installed advanced machinery with the help of which, we manufacture products as per the upcoming customers’ preferences and that too within stipulated time period.

Our company backed by specialized, skilled and adroit team of experts, who enabled us positioning our name in the list of top-notch firms of industry. It is because of their sound knowledge and vast experience of the respective domain. We conduct training programs on regular intervals to keep our employees aware and updated with the market growing preferences.

Our company is one amongst the reputed organizations, which is highly praised for making delivery of the products according to customers’ expectations. We ensure timeliness in the delivery of orders made by the clientele and also ensure maintaining excellence in the same.

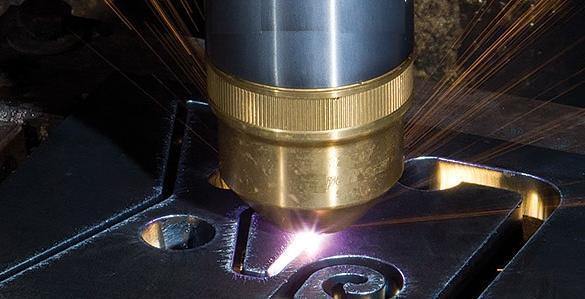

CNC CUTTING MACHINE

- LIGHT DUTY CNC CUTTING MACHINE for Flame & Air Plasma Source

- HEAVY DUTY CNC CUTTING MACHINE for Flame & Air Plasma Source & Hy-definition Plasma

- STRIP CUTTING MACHINE for Flame straight cutting only

- Note: *Plasma Cutting Thickness depends on selection of Plasma Source. Recommended cutting thickness for Strip cutting is above 10mm **Provided as optional based on the requirement and application specification varies to suit your requirement.

- More Details

Genral Product

- SELF CENTERING / CONVENTIONAL ROTATORS

- HSELF ALIGNED ROTATORS

- WELDING POSITIONER

- TURN TABLE

- HEAD & TAIL STOCK

- COLUMN & BOOM

- LONGITUDINAL SEAM WELDERS

- PORTABLE FLAME AND AIR PLASMA CUTTING MACHINE

- *Note: Air Plasma Cutting Thickness depends on selection of Plasma source. Either one of the head flame or plasma can be used for cutting. Both cannot be mounted portable cutting machine. **Provided as optional based on the requirement and application specification varies to suit your requirement.

- More Details

HEAVY BEAM WELDING AUTOMATION LINE

- 1. CNC CUTTING MACHINE WITH STRIP CUTTING TORCH’S

- 2. BEAM ASSEMBLY AND TACK WELDING EQUIPMENT WITH CONVEYORS

- 3. AUTO BEAM FULL WELDING EQUIPMENT WITH CONVEYORS AND BEAM HANDLING EQUIPMENT

- 4. FLANGE WARPAGE EQUIPMENTWITH IN-FEED & OUT FEED CONVEYORS

- 5. END FACING MACHINE WITH SUPPORT TABLE

- 6. SHOT BLASTING MACHINE WITH IN-FEED & OUT FEED CONVEYORS

- 7. HYDRALIC POWER PACK

- 8. WEDLING POWER SOURCE (MIG & SAW)

- 9. OTHER ACCESSORIES

- More Details

LONG SEAM WELDER

- Standard designs have welding lengths ranging from 500 mm to 3000 mm and part diameter ranges from 80mm to 1000 mm.

- For seam welding cylinders, tanks, flat sheets with GTAW, GMAW and SAW processes.

- Standard, Precision and Ultra-Precision versions available.

- Can be custom built to meet customer’s requirement.

- Side beam track is fitted with hardened ways for smooth precise travel.

- Carriages use hardened bearings or wheels and AC/DC motor drives.

- Continuous Foot Amptrol to operate the pneumatic finger banks.

- Various speed ranges and speed holding accuracies are available.

- Copper backing bars and copper finger tips are standard.

- For welding 0.5 mm to 8 mm thick metals.

- *Based on the requirement and application specification varies to suit customer’s requirement.

- More Details

PEB – BEAM WELDING AUTOMATION LINE

Invent Weld PEB Beam welding systems are used to automatically weld the Flange plate to a web plate to form a Pre-fabricated Beam. The beam line equipment comprise of conveyors, Web Splice welders. Tack welding machine, Pull through welder (Auto Welder), Twin wire SAW welding machine (Power source, wire feed head and controller), Pre settable welding heads and flux recovery units.

Invent offers total solution for Automatic and Manual welding of beams. Invent beam line for PEB includes CNC Plasma/Flame head cutting machine, Web/Flange Splice welder, Flange to Web Tack welder, Pull through Welder (Auto welder), Twin Wire SAW welding machines, Conveyors, etc. Invent provide comprehensive material handling system to support beam welding line.

Invent offers PEB Beam Welding line to customers based on production capacities which helps customer to start producing beams with lesser investment and can be enhanced at later stage based on the volume increase. This will be more helpful for the startup companies. We offer equipment’s from the range of 250 tons to 1000 tons per month productivity.

TURNKEY SOLUTION FOR WIND TOWER FABRICATION

- 1. CNC PLATE CUTTING MACHINE WITH PLASMA SOURCE

- 2. CNC PLATE BENDING WITH IN-FEED CONVEYING DEVICE

- 3. PLATE BEVELLERS – MECHANICAL TYPE

- 4. LONG SEAM WELDING STATION HAVING a. ROTATOR SETS b. COLUMN AND BOOM FOR SUB-ARC WELDING

- 5. FIT-UP FIXTURE FOR FLANGE TO STUB SHELL

- 6. BOTTOM FLANGE & BOTTOM SHELL FULL WELDING UNIT

- 7. GROWING LINE FOR SHELL TO SHELL FIT-UP

- 8. CIRC-SEAM WELDING STATION HAVING a. ROTATOR SETS b. COLUMN AND BOOM FOR SUB-ARC WELDING

- 9. ROTATORS SETS FOR BLASTING AND PAINTING BOOTHS

- More Details